Delivering £17.8M savings over 10 years for a food & beverage manufacturer

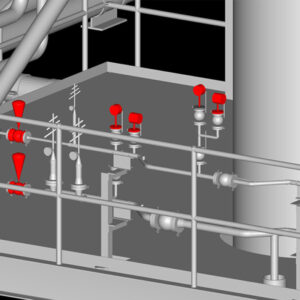

£17.8M SAVING over 10 years <3 years Payback 3 * WASTE HEAT BOILERS & GAS ENGINES 2,000 kg/hr, 7.5barg Waste heat recovery boilers 3.355 MWe gas enginespx was commissioned by a large soft drinks manufacturer to complete a concept study and a Front End Engineering Design (FEED) study for its proposed 9.9 MWe Combined Heat and Power Plant (CHP) at its main manufacturing facility.

What We Did

The objective of the FEED study was to provide sufficient detail to allow a cost estimate of +/- 10% to be provided and also to enable an Engineering, Procurement and Construction Management (EPCM) contract to be entered into for the CHP Plant.

The output from the FEED study is to be utilised as a basis for the detailed engineering design to be undertaken by the EPCM contractor.

The commercial information gathered by the FEED study and from the customer was used to develop a 10 year financial model. This identified the potential savings, payback and IRR for the investment.

Results

The CHP plant will produce up to 20,000 kg/h, 7.5barg dry saturated steam and approximately 1500 kWth of hot water, which is supplied to an absorption chiller to provide a 1000 kWth of chilled process water.